Industrial Equipment

SRI offers you

Advice and support to choose the best industrial equipment to fulfill your production needs.

Equipment Installation Services

Maintenance

Spare parts

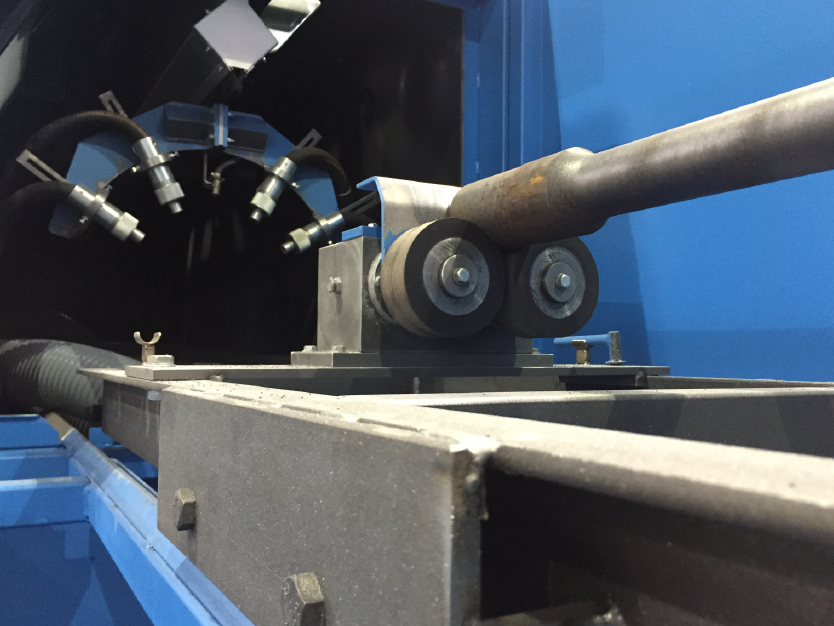

Shot Blasting Machines

Complete systems and machines for shot-blasting and shot-peening to clean, descale, strengthen (peen) or aesthetically finish metal in many different fields.

- Overhead conveyor blast machines

- Tumble belt blast machines

- Rotary table blast machines

- Belt conveyor blast machines

- Roller conveyor blast machines

- Compressed air sandblasters

- Special Systems

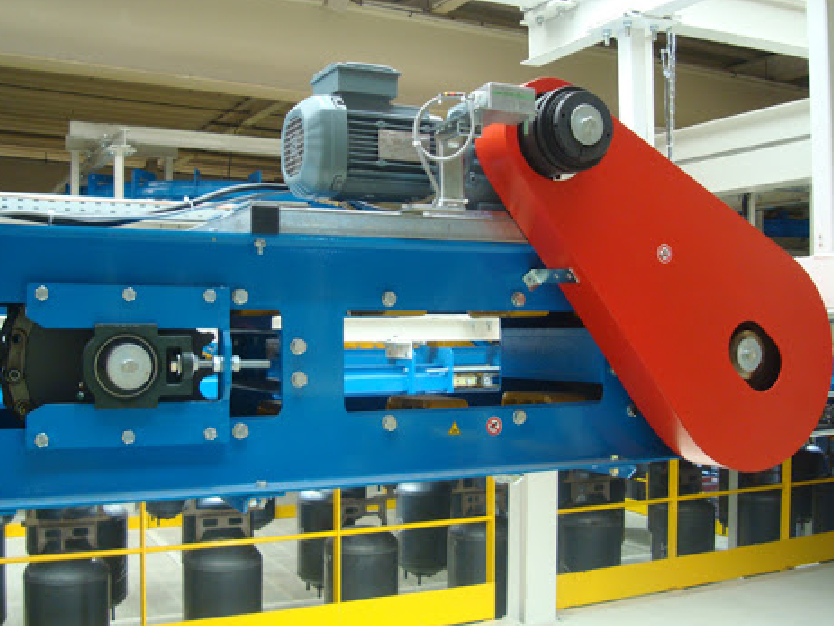

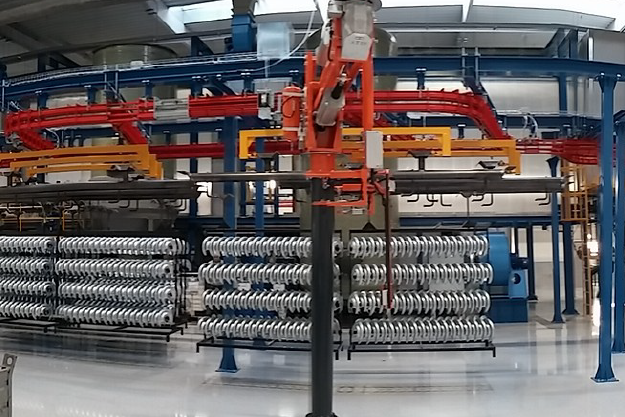

Overhead Conveyors

Conveyors manufacture & design: twin rail, single rail and special products for overhead conveyors. Our conveyors are designed for the automated transport of any product type and are suitable for assembly lines, dynamic storage facilities, powder paint, immersion paint and enamel production lines.

Main advantages:

- Easy assembly and disassembly

- Maximum flexibility, allowing for the creation of transport lines of varying configurations

- High quality production and assembly of each individual component

- Exceptional durability and reliability

- Minimum maintenance required

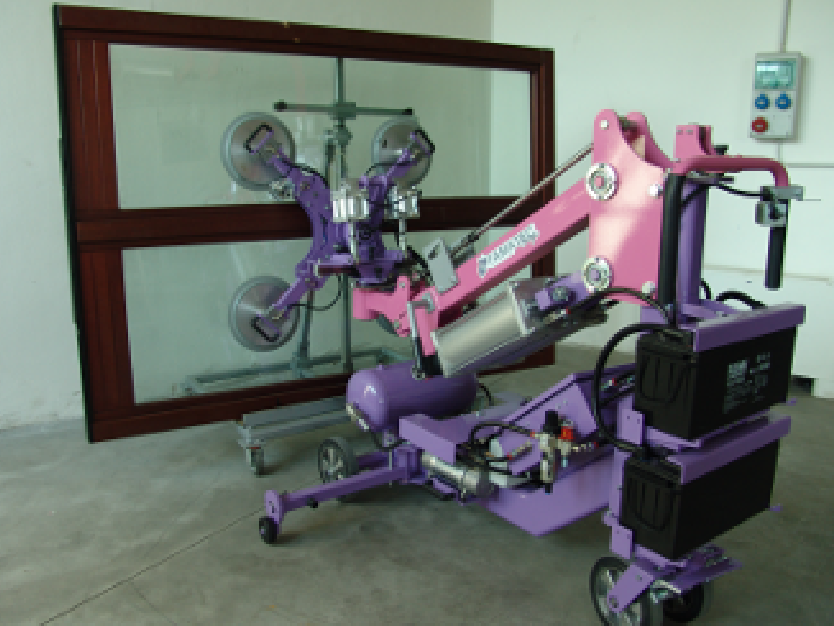

Manipulators

Handling solutions for loads in the manufacturing industry. Zero gravity manipulation solutions for every kinds of industries. Our manipulators are customized according to production’s needs, ligth and ergonomic, with the ideal gripper according to the material: Gripping with suction cups, Hooks, Handling bags with suction pads, Gripping system with magnet, Gripping with clamps.

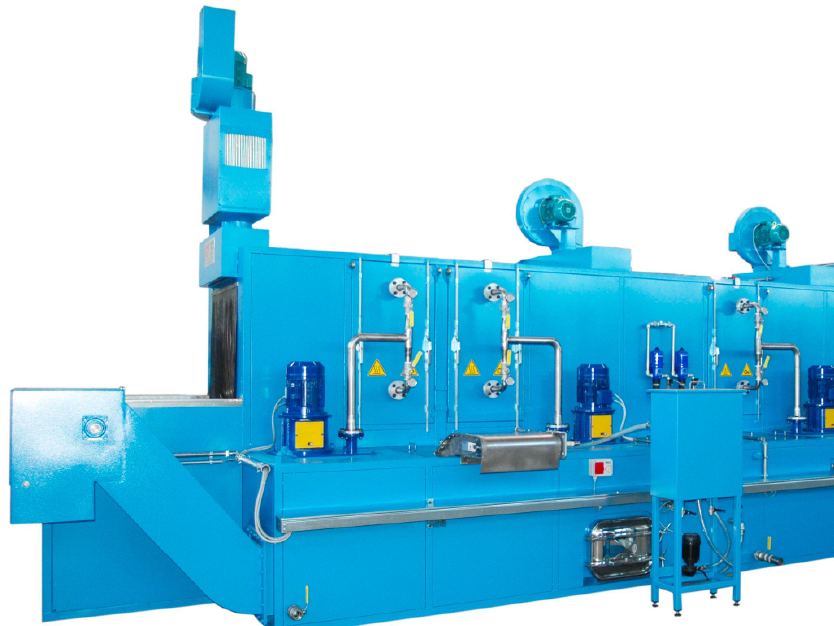

Industrial Washers

Industrial water washing systems combine the water properties, technology, the cleaning solution as well as the time required for a complete cycle.

According to production needs, customized solutions are studied, with maximum energy optimization focus, reuse of water, time and costs savings, to ensure efficiency and productivity improvement. We have a wide range of industrial washing systems and we advise each client not only on the most suitable washing cycle, but also on the correct process to gain the best expected result. Each client has his own procedure that requires an ad-hoc solution, so we offer the acurate process with the correct decontaminant; alcohol, water or solvent.

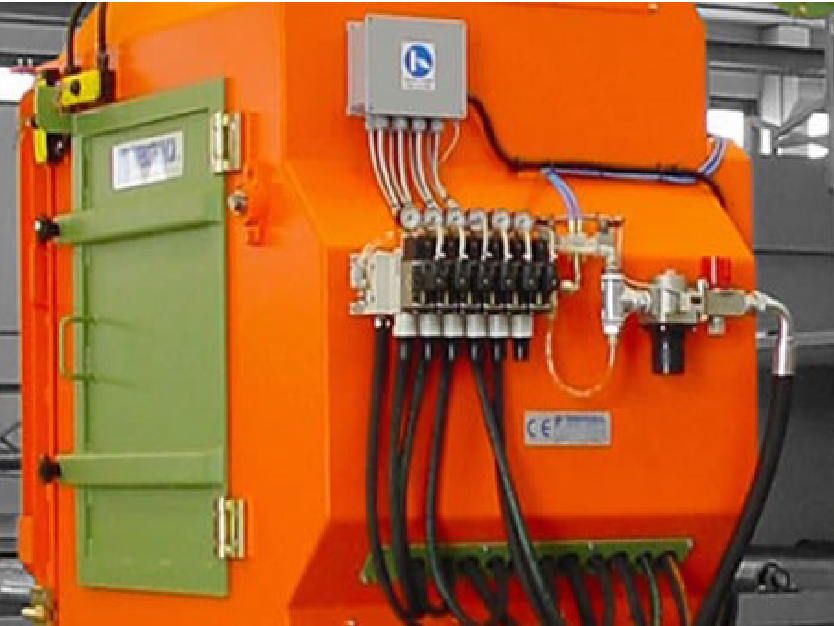

Painting Systems

Customized painting systems. Complete plants for all surface finishing technologies, such as: liquid paints (water or solvent based), applied by spray methods, by immersion, by flow coating, by electrodepositing (anodic or cathodic), to cover the protection and finishing of any type of surface, either in metal or in plastic.

Leaktesting Systems

Industrial solutions for leaktesting control using measure systems by masospectrometry with helium or other gases. Useful for many manufacturing sectors, including: refrigeration and conditioning, air treatment, automotive, packaging, chemical, pharmaceutical, electromedical, aerospace, mechanical and electronic.

- Leaktesting machines and installation.

- Preparation and recovery test gas systems.

Industrial Ovens – BENKO PRODUCTS

Innovative, high-quality, and cost-effective solutions for a variety of industrial material handling applications.

Various designs of large-scale batch, conveyor, and cabinet ovens used in numerous applications.

- Sahara Drum/Tote Ovens

- GREEN Access and Fall Protection

- Industrial Ovens / Batch Ovens

- Protect-O-Gate Industrial Safety Gates

- Environmental Products / Hazmat Storage

- G-Raff / Safety Systems

- Husky / Industrial Refrigerators / Freezers